STEAM BOILERS

DB BOILERS

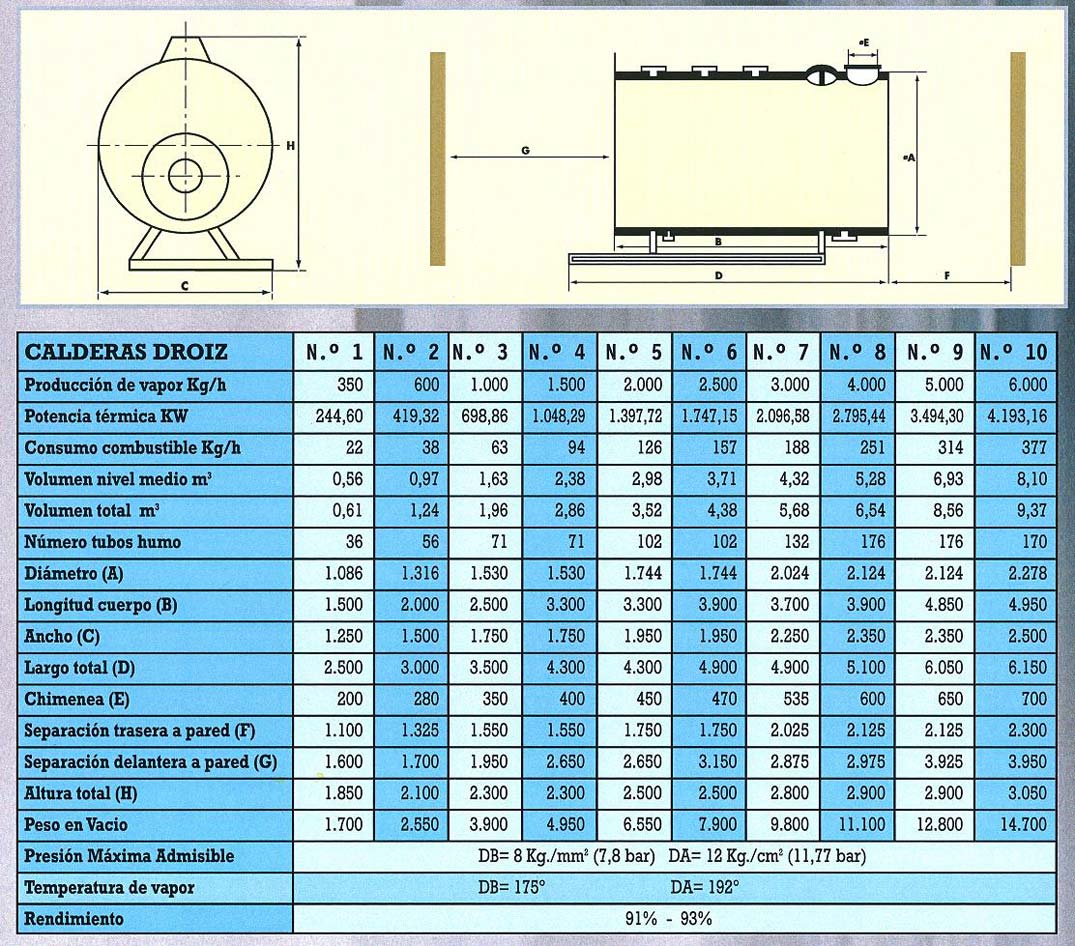

A RANGE OF 10 MODELS, FROM 245 Kw (350 Kg/h) to 4,193 Kw (6,000 Kg/h) and up to 7.8 bar pressure.

- Category I and II boilers, according to power and pressure.

- Fire-tube boiler with 3 smoke passages: 1 for the fire box, where full combustion takes place, y 2 for the smoke tubes.

- Mandrel tubes (not welded to plates).

- The manufacturing materials are carefully selected to ensure the best quality and durability of the boilers.

- Our design produces boilers with a low thermal load and reduced levels of air pollutants (NOx y CO).

- The boiler is 100% accessible from the outside, there is no need to enter through the furnace, openings or windows to perform interior maintenance.

- Hermetically sealed doors with quick-opening via through bolts.

- The boiler can be adapted for right-hand or left-hand control.

- Certified manufacture under PED 97/23CE.

- It can burn any type of liquid or gaseous fuels.

- Adaptable to any brand of burner.

- Large diameter fire box with low thermal load, which is pressurised for combustion, complying with environmental regulations.

- Smooth or corrugated fire box, depending on the model.

- Water-cooled fire box, accessible from the outside.

- As an internal safety measure, there is an alloy fuse in the fire box.

- The boilers have an expansion valve at the end of the fire box -exclusive to Talleres Patricio Ruiz- which opens automatically in the event of overpressure in excess of what is standardised to allow this excessive gas pressure to escape without damaging the combustion chamber, tubes or other internal parts.

- High efficiency (91-93 %) with low flue gas outlet temperature.

- Thick, high-density external thermal insulation for low radiant heat loss.

- Stainless steel vertical electric pump unit with low consumption and high pressure and flow.

- Ladder to access the platform at the top of the boiler (depending on the model).

- Water level controls in the boiler by means of electronic probes.

- Thanks to the design of the smoke tubes layout with a wide separation between them, the water recirculation is good, achieving optimum heat transmission and low resistance to the passage of smoke.

- The boilers leave our workshops mounted on a metal base that forms a set with the other accessories, making a quick installation easy.

- The dry steam obtained by the good relation between the volume of the water level and the steam chamber gives this boiler a high vapor quality.

- The intuitive electric control panel indicates at all times the status of the boiler.

- The boilers can leave our workshops with 2-, 24- or 72-hour surveillance control, depending on the needs of each client, and under TRD 604 safety standards.

- The external finish of the boiler is bright stainless steel.

- The boilers have several large openings for inspection and cleaning of the wet area.

- At the top of the boiler there is a large manhole, which allows the operator access to the wet area of the boiler.

- Throughout the manufacturing process, the boiler is assessed by an Authorised Control Body (ACO) in order to receive the boiler CE Marking verification.