STEAM BOILERS

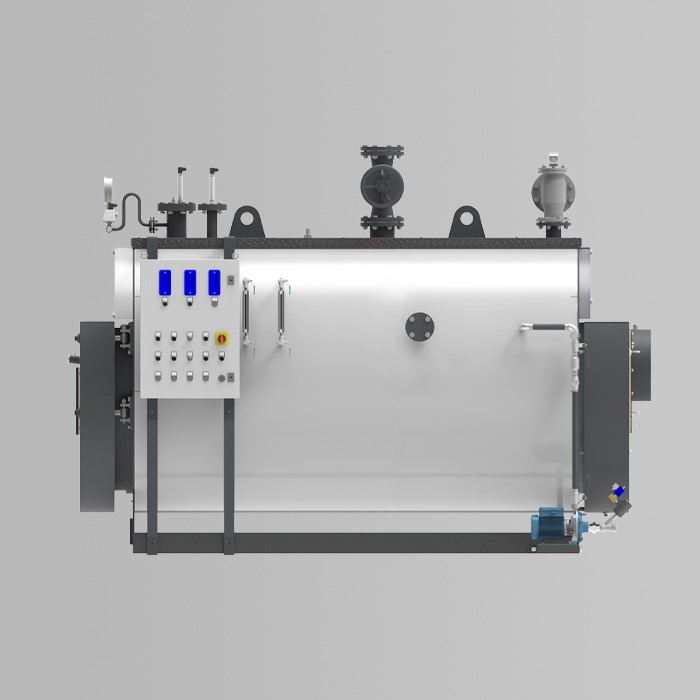

1OR BOILER

Boilers for low pressure to 0.98 bar.

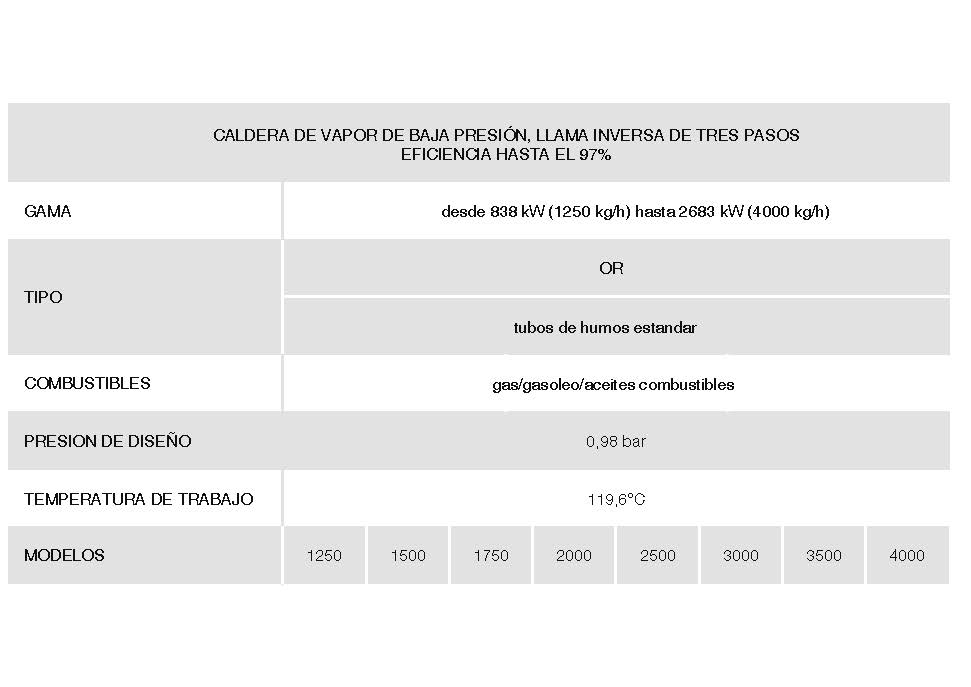

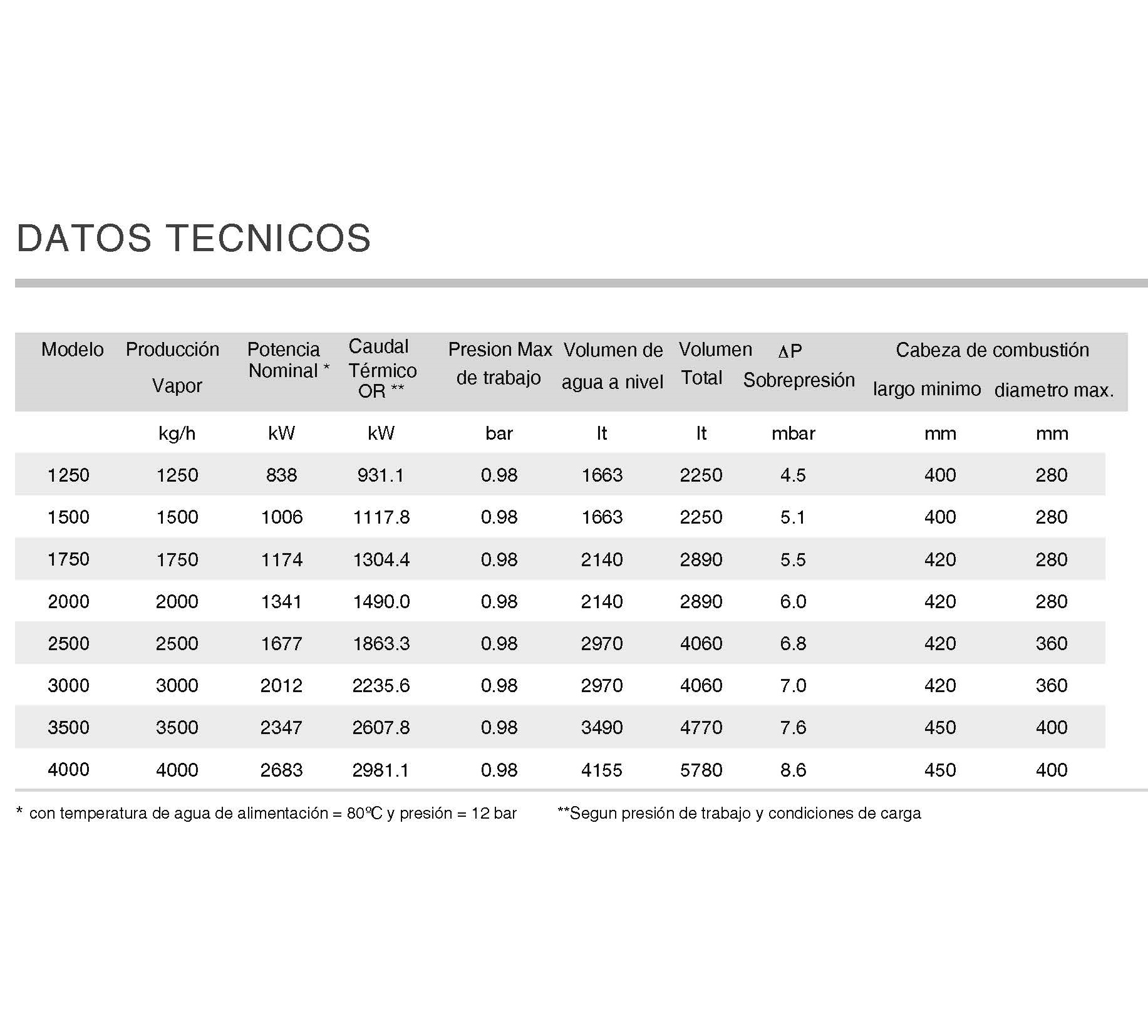

A RANGE OF 13 MODELS, from 134 Kw (200 Kg/h) to 2,012 Kw (3,000 Kg/h)

- Category I boilers.

- High performance fire-tube boiler with 3 smoke passages and flame reversal furnace.

- Boiler with a large diameter cylindrical furnace, where the burner flame rotates at the bottom, which is also bathed in water, and returns to the front door to pass into the flue pipes, with a low thermal load.

- The smooth smoke tubes have helical turbulators to improve the heat exchange of the smoke, guarantee lower pressure losses and obtain high efficiencies of over 91%; this performance can be increased by more than 5% by installing an economizer.

- At the top of the boiler there is a large manhole, which allows the operator access to the wet area of the boiler.

- Opening upper walkway.

- Efficient thermal insulation of high thickness mineral rock wool with aluminium backing. Separation between the hot parts of the boiler body and the casing to eliminate heat bridges.

- Reversible opening of the door by adjusting the hinges and locking straps in all directions.

- Electrical connections with quick-fit connectors.

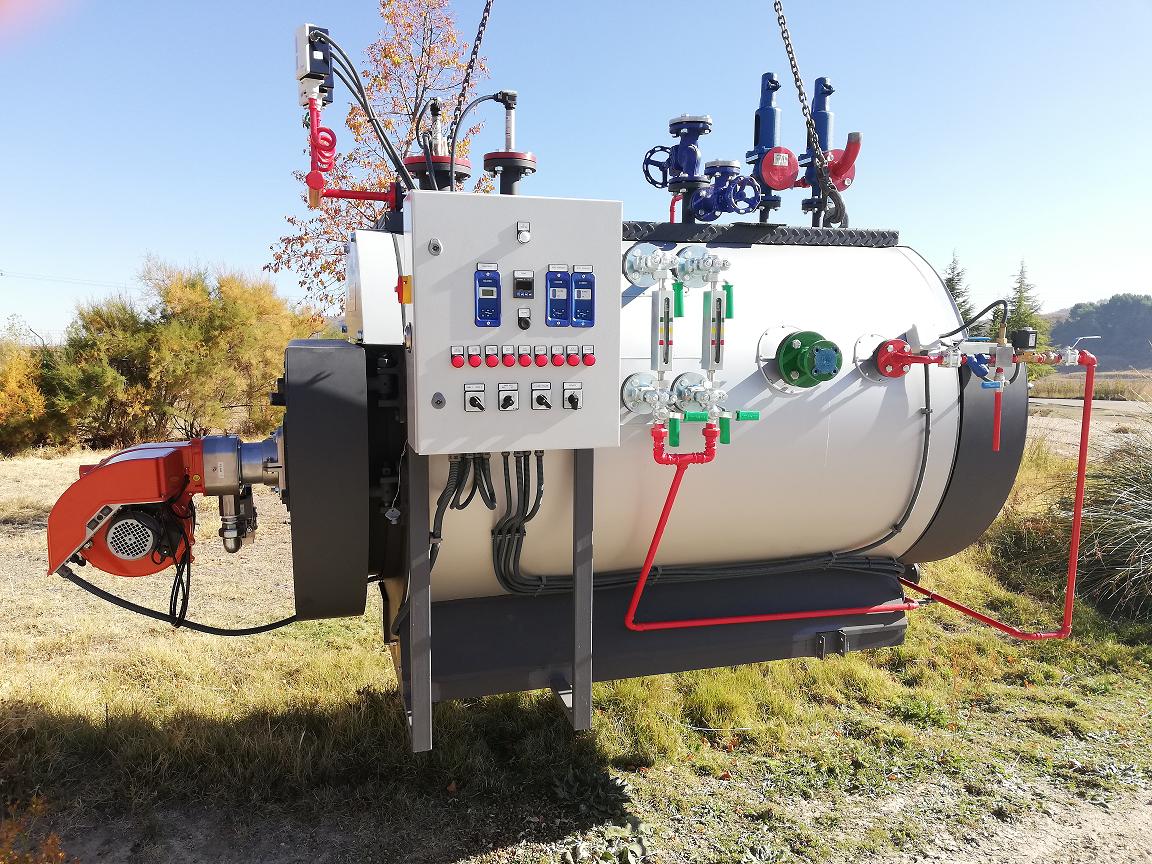

- Expandable electromechanical and electronic control panels (optional).

- It can burn any type of liquid or gaseous fuels.

- Adaptable to any brand of burner.

- The boiler can be adapted for right-hand or left-hand control.

- Ladder to access the platform at the top of the boiler (depending on the model).

- Functions that can be implemented with optional kits, also with boilers already installed. Stainless steel vertical electric pump unit with low consumption and high pressure and flow.

- Water level controls in the boiler by means of electronic probes.

- The dry steam obtained by the good relation between the volume of the water level and the steam chamber gives this boiler a high vapor quality.

- The boilers leave our workshops mounted on a metal base that forms a set with the other accessories, making a quick installation easy.

- Certified manufacture under PED 97/23CE.

- Optional components to be fitted in the boilers:

- 7”PLC control panel.

- Salt purge system.

- Sludge purge system.

- 24 or 72-hour safety kit.

- 2nd feed pump kit.

- Economiser kit– 5% performance increase.

- Water supply modulation kit.

- Boiler sampling kit.

- Kit for protection against dry running of the water pump.

- Web remote control kit via 3G or ADSL.

SCHUSTER IS A BRAND REPRESENTED BY TALLERES PATRICIO RUIZ

Previous

Next