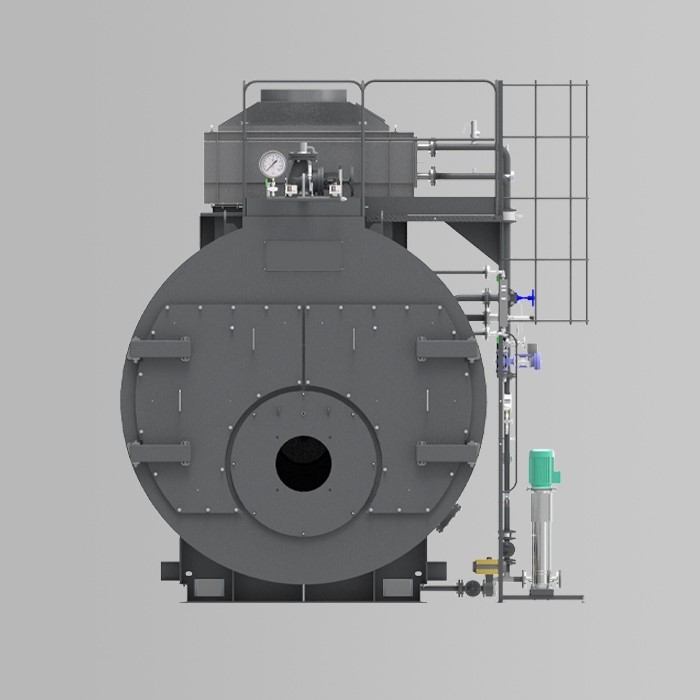

STEAM BOILERS

3'12 BOILER

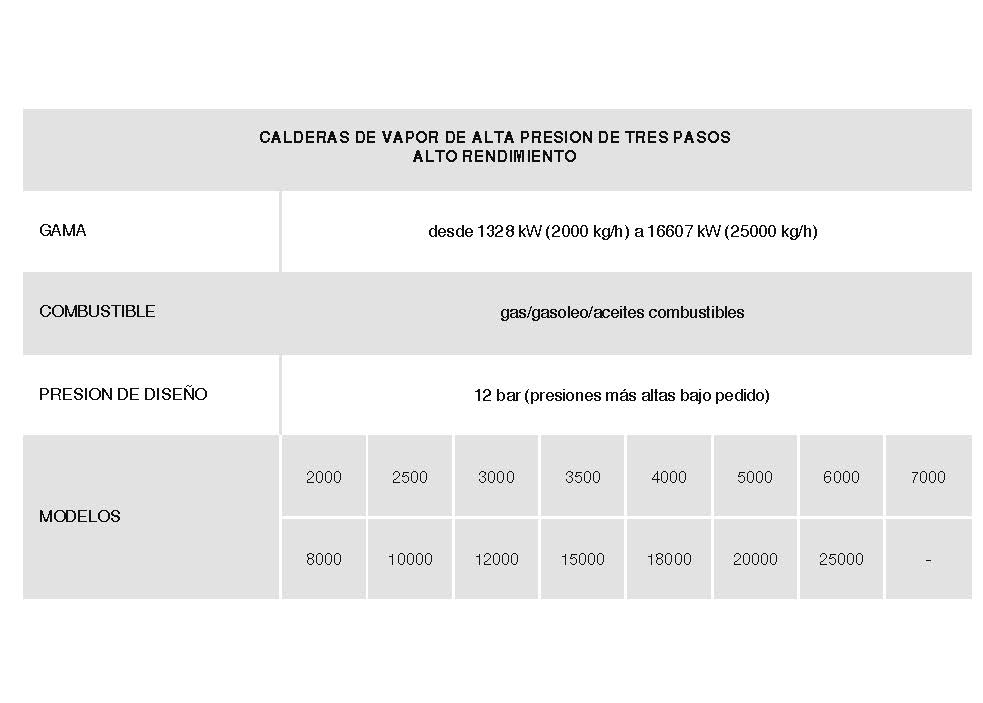

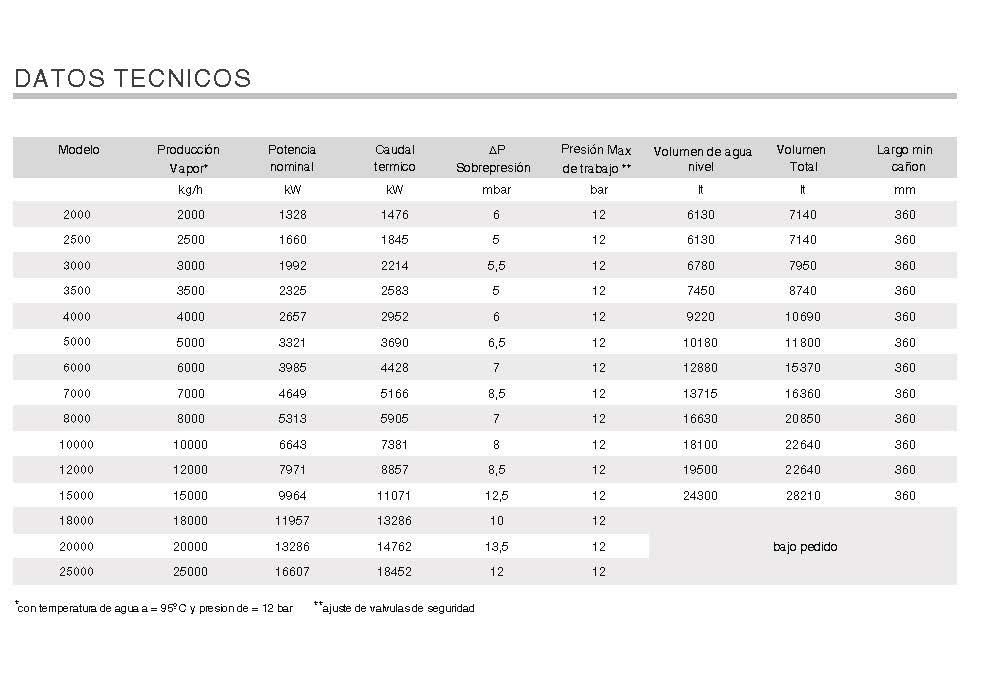

A RANGE OF 15 MODELS, FROM 1,328 Kw (2,000 Kg/h) to 16,607 Kw (25,000 Kg/h) and up to 12 bar as standard or more if necessary.

- Category I and II boilers, according to power and pressure.

- 1 for the fire box, where full combustion takes place, y 2 for the smoke tubes.

- Mandrel tubes welded to plates.

- The manufacturing materials are carefully selected to ensure the best quality and durability of the boilers.

- Our design produces boilers with a low thermal load and reduced levels of air pollutants (NOx y CO).

- The boiler is 100% accessible from the outside, there is no need to enter through the furnace, openings or windows to perform interior maintenance.

- Hermetically sealed doors with quick-opening via through bolts.

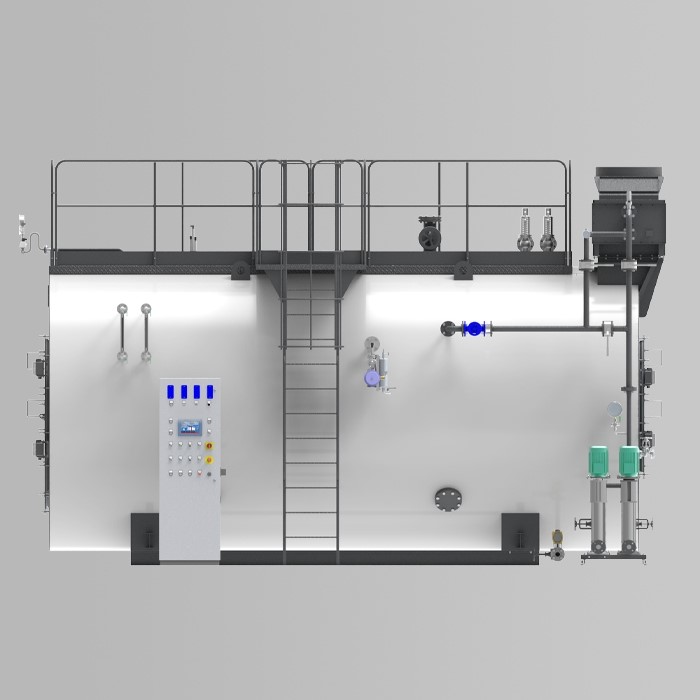

- The boiler can be adapted for right-hand or left-hand control.

- Certified manufacture under PED 97/23CE.

- It can burn any type of liquid or gaseous fuels.

- Adaptable to any brand of burner.

- Large diameter fire box with low thermal load, which is pressurised for combustion, complying with environmental regulations.

- Smooth or corrugated fire box, depending on the model.

- Water-cooled fire box, accessible from the outside.

- High efficiency of 90 – 96% with low flue temperature.

- Thick, high-density external thermal insulation for low radiant heat loss.

- Stainless steel vertical electric pump unit with low consumption and high pressure and flow.

- Ladder to access the platform at the top of the boiler (depending on the model).

- Water level controls in the boiler by means of electronic probes.

- Thanks to the design of the smoke tubes layout with a wide separation between them, the water recirculation is good, achieving optimum heat transmission and low resistance to the passage of smoke.

- The boilers leave our workshops mounted on a metal base that forms a set with the other accessories, making a quick installation easy.

- The dry steam obtained by the good relation between the volume of the water level and the steam chamber gives this boiler a high vapor quality.

- The intuitive electric control panel indicates at all times the status of the boiler.

- The boilers can leave our workshops with 2-, 24- or 72-hour surveillance control, depending on the needs of each client, and under TRD 604 safety standards.

- The exterior finish of the boiler is 10/10 mm painted sheet metal. of thickness.

- The boilers have several large openings for inspection and cleaning of the wet area.

- At the top of the boiler there is a large manhole, which allows the operator access to the wet area of the boiler.

- Throughout the manufacturing process, the boiler is assessed by an Authorised Control Body (ACO) in order to receive the boiler CE Marking verification.

SCHUSTER IS A BRAND REPRESENTED BY TALLERES PATRICIO RUIZ